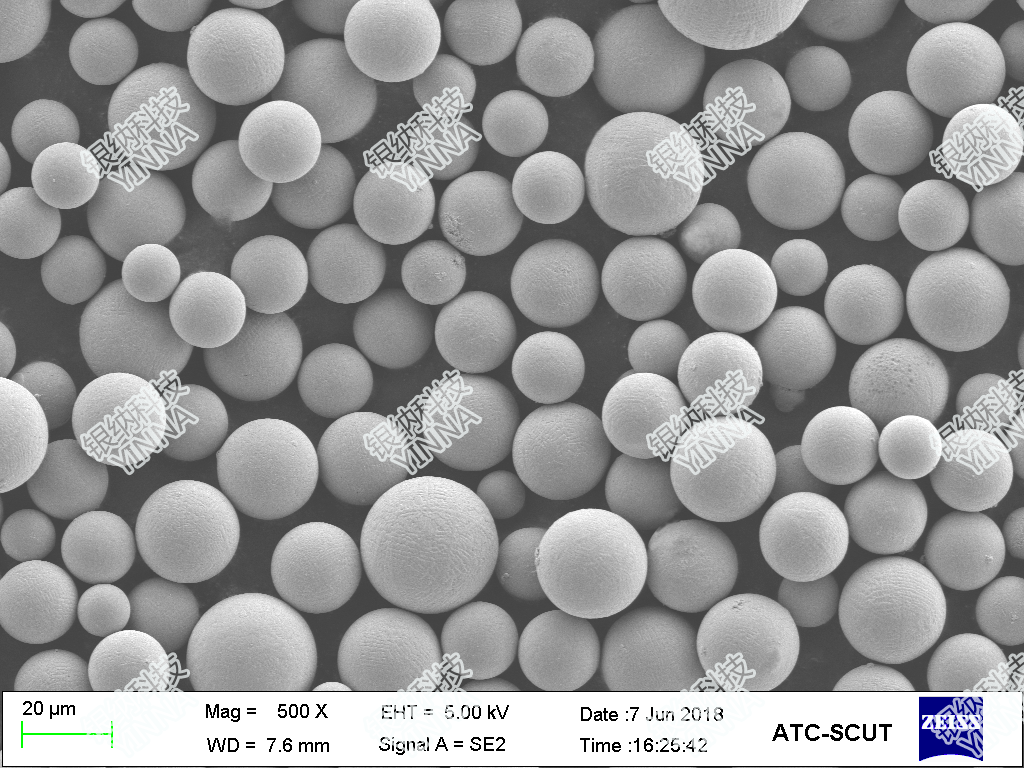

Spherical powder of nickel base alloy

Shape sphericity

Particle size standard 10-45um; customized interval 1um-150um

? purity >99.9%

3D printing applications: SLM selective laser melting, EBM electron beam melting, LMD laser metal deposition, and other applications: Powder Metallurgy (PM), injection molding (MIM), thermal isostatic pressure (HIP), spraying (SP), welding repair and so on.

1. detailed information

Alloy | Chemical composition(wt.%) | |||||||||||

IN625 | Ni | Cr | Mo | Nb | Fe | Ti | Al | |||||

Bal | 20-23 | 8-10 | 3.15-4.15 | ≤5.0 | ≤0.4 | ≤0.4 | ||||||

Co | Mn | Si | Cu | C | O | |||||||

≤1.0 | ≤0.5 | ≤0.5 | ≤0.07 | ≤0.1 | ≤0.02 | |||||||

IN718 | Ni | Cr | Mo | Nb | Fe | Ti | Al | |||||

50-55 | 17-21 | 2.8-3.3 | 4.75-5.5 | Bal | 0.65-1.15 | 0.2-0.8 | ||||||

Co | Mn | Si | Cu | C | O | |||||||

≤1.0 | ≤0.35 | ≤0.35 | ≤0.30 | ≤0.08 | ≤0.02 | |||||||

Particle size range(μm) | 10-25 | 15-45 | 30-60 | 50-120 | ||||||||

Morphology | spherical | |||||||||||

particle size distribution | D10 | 12 | 20 | 32 | 56 | |||||||

D50 | 18 | 28 | 45 | 83 | ||||||||

D90 | 24 | 38 | 56 | 104 | ||||||||

Mobility(s/50g) | ≤23 | ≤20 | ≤18 | ≤16 | ||||||||

Density of loose fitting(g/cm3) | 4.24 | 4.46 | 4.61 | 4.89 | ||||||||

oxygen content(PPM) | ≤200 | |||||||||||

Sphericity: spherical or nearly spherical, spherical particle size 0, or more than 0.85.

Appearance quality: visual gray, no obvious oxidized particles.

Preparation process: vacuum melting mother alloy + vacuum induction pure smelting + supersonic gas atomizing powder + screening grading + Inspection package.

3D printing applications: SLM selective laser melting, EBM electron beam melting, LMD laser metal deposition, etc.

Other applications: powder metallurgy (PM), injection molding (MIM), hot isostatic pressing (HIP), spraying (SP), welding repair, etc.

Online

consultation